欢迎光临:

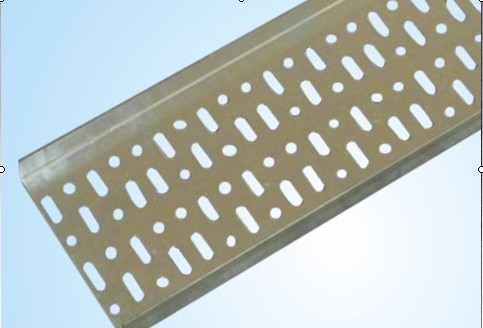

在电缆桥架安装中应用激光投线定位法

电气安装工程中,电缆桥架的安装进度对整个工程影响最大。激光投线仪是一种新型的光机电一体化仪器,它采用波长为635nm的半导体激光器,激光线清晰明亮,适合于较远距离的投线定位,发射器采用专用供电电源,具有强抗干扰性、高稳定性、抑制浪涌电流等特点,特别适于恶劣的工作环境,能有效保证镭射激光头的稳定性和使用寿命。

激光投线仪具有重力感应功能,通过气泡调节自身水平后可以方便的投射出多条投射线,投射线在室内50米范围清晰可见,对线时,慢慢转动投射转盘,待投射线由远到近刚好到达立柱或托臂边缘时,拧死锁定旋钮,将投射转盘固定。采用激光对线法可以节省人工作业的弹线和挂吊锤等步骤,减少挂吊锤和反复测量的时间。使用激光投线定位取代人工测量定位后,桥架安装改进工艺流程为:激光投线定位→膨胀螺栓安装→立柱、托臂安装→电缆桥架安装→电缆桥架接地。用激光投线仪定位托臂的位置,首先根据图纸确定各层托臂的标高,先找准并固定好每层首尾两端的托臂(包括中间转弯处)。水平投射线在室内50米范围清晰可见,可以作为定位线由远到近安装托臂,节省每条立柱划托臂定位线这一步骤。用激光投线仪逐一确定每条托臂的标高,保证桥架的连接板中心线在同一直线上。具体实施步骤为:

(1)在其中一条立柱上测量电缆桥架托臂的定位线,调节#2激光投线仪的水平投射线高度,使投射的水平线与该定位线高度一致。

(2)托臂对准水平投射线临时点焊固定,用铁锤轻敲电缆桥架托臂细调其位置,使托臂与水平投射线完全重合,再用水平尺检查其水平。全部的电缆桥架托臂均确定到达水平位置后,再用电焊固定。

The laser projection method is used in cable bridge mounting.

In electrical installation engineering, the installation progress of cable bridge is the most important to the whole project.

The laser projector is a new type of optical and electromechanical integrated instrument. It adopts a semiconductor laser with a wavelength of 635nm. The laser line is clear and bright. It is suitable for the positioning of the casting line at a long distance.

The transmitter adopts the special power supply, which has the characteristics of strong anti-interference, high stability, and restrains the surge current, especially suitable for the bad working environment, which can effectively guarantee the stability of laser head of laser.

Sex and service life.

The laser projection instrument has the function of gravity induction, which can be easily projected by the air bubble to adjust its own level. It can be clearly visible within 50 meters of the room.

Slowly rotate the projection wheel, and when the beam is from the distance to the upright post or to the edge of the bracket, twist the locking knob to fix the projection wheel. Laser alignment can save labor.

To reduce the time of hanging hammer and repeated measurement. After replacing the manual measurement positioning with the laser projection line positioning, the improvement process of the bridge erection is as follows:

Laser projection positioning - expansion bolt installation - column, bracket installation - cable bridge mounting - cable bridge grounding.

The position of the supporting arm is positioned with the laser pointer. First, the elevation of each layer is determined according to the drawing, and the supporting arm at both ends of each floor (including the center corner) is first identified and fixed. Horizontal projection

It is clearly visible within 50 meters of the room, which can be used as the positioning line to install the bracket from far to near, saving the step of the positioning line of each column. Use the laser pointer to determine the elevation of each arm.

To ensure that the center line of the connecting plate of the bridge is on the same line. The specific implementation steps are:

(1) measure the positioning line of the cable bridge bracket on one of the columns, and adjust the horizontal projection height of the #2 laser projector, so that the horizontal line of the projection is in line with the positioning line.

(2) the alignment of the bracket arm horizontal cast rays temporary fixed spot welding, tapping cable bridge arm hammer fine tuning its position, make the bracket and horizontal rays coincide, reoccupy level check its level.

All cable bridge bracket arm is determined to reach the horizontal position, then fixed with electric welding.

Contact Us

友情链接: