欢迎光临:

电缆桥架主要用于供电配套电力输送及有线电信转送等综合布线,敷设电缆的支撑构件。这种支撑构件在电力供应部门,工矿企业、酒店、综合办公设施的集中供配电的电力输送系统及有线电信等应用最广泛。电缆线在正常工作时要散发大量的热量,而现有托盘式桥架底板多为整体式平板,缺少散热结构,不利于电缆线的散热,电缆线长时间处于高温下势必影响其使用寿命。桥架安装时需要将多个桥架通过侧板连接在一起,因此桥架侧板两端会设有连接孔,而现有桥架连接孔大多只有一个,且形状多为与连接螺栓匹配的圆形,不能根据实际情况进行调节,增加了装配的难度,不利于装配效率的提高。

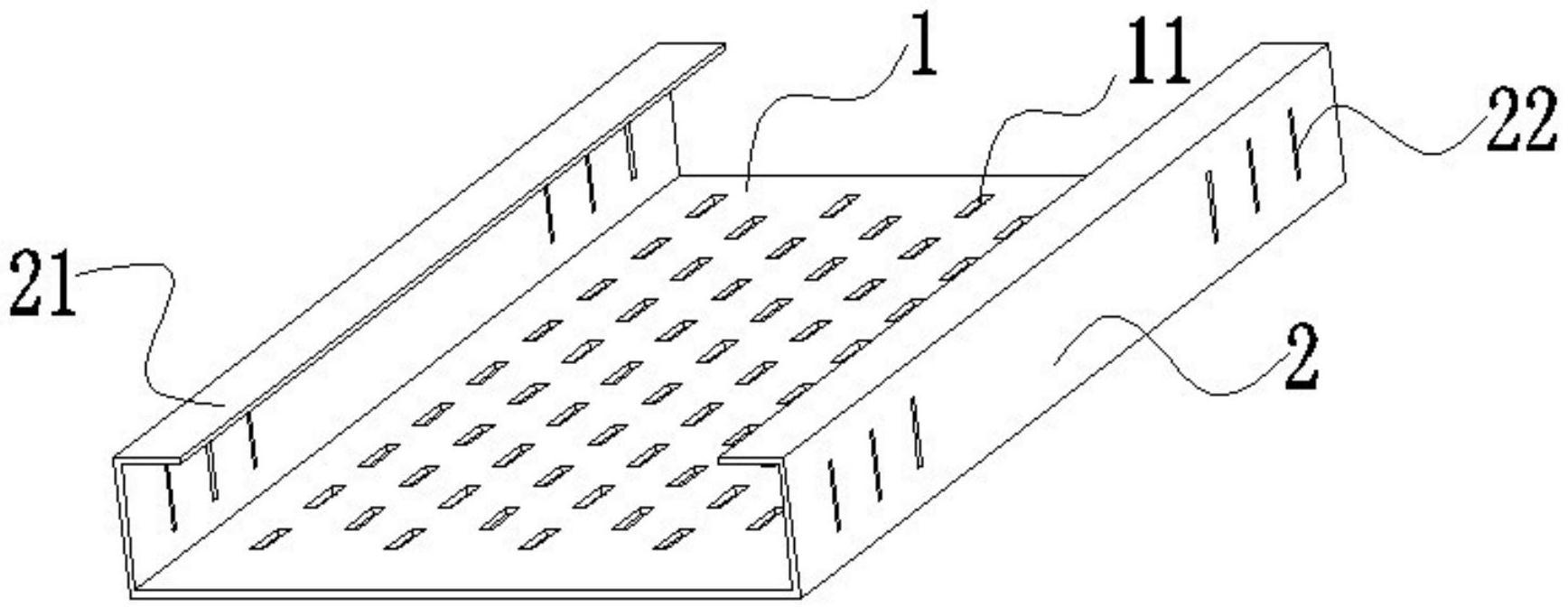

本发明的目的是克服现有技术存在的缺陷,提供一种散热好、安装方便的托盘式电缆桥架。实现本发明目的的技术方案是 :一种托盘式电缆桥架,具有底板和与底板两侧固定连接的侧板 ;所述底板和侧板一体成型 ;所述底板上还设有若干散热孔。上述技术方案,所述散热孔呈圆形、长方形、正方形或键槽形,所述若干散热孔均布在底板上。上述技术方案,所述侧板上部设有翻边,侧板侧面两端均设有多个连接孔。上述技术方案,所述侧板一端上的连接孔有 3 个,连接孔形状为键槽形。上述技术方案,所述底板的宽度为 200 ~ 1000mm,所述侧板高度为 60 ~ 200mm,侧板长度为 2000mm。

采用上述技术方案后,本发明具有以下积极的效果 :

(1)本发明底板和侧板一体成型,简化了生产工艺,提高生产效率,节约生产成本 ; 且底板上设有多个散热孔,可大大提高散热效率,有效提高了电缆线的使用寿命,另一方面 还可降低电缆桥架的重量 ;

(2)本发明侧板上翻边可用于桥架上部封盖的插装连接,侧板上连接孔平行设置多个,且形状设计为键槽型,可根据实际情况选择合适位置的连接孔进行连接,使安装更方便,能够大幅度提高安装效率 ;

(3)本发明结构简单,造型别致,成本低,强度高,即适用于动力电缆的安装,也适用于控制电缆敷设。

具体实施方式

本发明具有底板1 和与底板1 两侧固定连接的侧板2 ;其特征在于 :所述底板 1 和侧板 2 一体成型 ;所述底板 1 上还设有若干散热孔 11。

优选地,所述散热孔 11 呈圆形、长方形、正方形或键槽形,所述若干散热孔 11 均布在底板 1 上。

优选地,所述侧板 2 上部设有翻边 21,侧板 2 侧面两端均设有多个连接孔 22,本实施例连接孔 22 有 3 个,连接孔 22 形状为键槽形。

根据客户实际需求,底板 1 的宽度可为 200 ~ 1000mm,侧板 2 高度可为 60 ~200mm,侧板 2 长度可为 2000mm。

以上所述的具体实施例,对本发明的目的、技术方案和有益效果进行了进一步详细说明,所应理解的是,以上所述仅为本发明的具体实施例而已,并不用于限制本发明,凡在本发明的精神和原则之内,所做的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。 The cable bridge is mainly used for power supply supporting power transmission and cable telecommunication transmission. This kind of support component is most widely used in power supply department, power transmission system and cable telecommunication of centralized power supply and distribution of industrial and mining enterprises, hotels and comprehensive office facilities. Cable in normal work to send out a lot of heat, and the existing pallet bridge floor is integral plate more, lack of heat dissipation structure, bad for heat dissipation of cables, cables for a long time under high temperature is bound to affect its service life. Bridge installation time need to connect more than one bridge through the side panel together, so the bridge has the connection holes on both ends of the side panel, and most of the existing bridge connecting hole is only one, and the shape is round, with the connection bolt matching more cannot be adjusted according to actual condition, increased the difficulty of the assembly, assembly efficiency.

The cable bridge is mainly used for power supply supporting power transmission and cable telecommunication transmission. This kind of support component is most widely used in power supply department, power transmission system and cable telecommunication of centralized power supply and distribution of industrial and mining enterprises, hotels and comprehensive office facilities. Cable in normal work to send out a lot of heat, and the existing pallet bridge floor is integral plate more, lack of heat dissipation structure, bad for heat dissipation of cables, cables for a long time under high temperature is bound to affect its service life. Bridge installation time need to connect more than one bridge through the side panel together, so the bridge has the connection holes on both ends of the side panel, and most of the existing bridge connecting hole is only one, and the shape is round, with the connection bolt matching more cannot be adjusted according to actual condition, increased the difficulty of the assembly, assembly efficiency.

The purpose of the present invention is to overcome the defects of the existing technology and provide a tray cable bridge with good heat dissipation and convenient installation. The technical scheme for the purpose of the present invention is: a tray-type cable bridge with a bottom plate and a side plate fixed to both sides of the bottom plate; The bottom plate and side plate are formed in one piece; A number of heat dissipation holes are also arranged on the bottom plate. In the above technical scheme, the heat dissipation holes are round, rectangular, square or keyway shape, and the heat dissipation holes are arranged on the bottom plate. In the above technical scheme, the upper part of the side plate is provided with a flanging edge, and the two sides of the side plate are provided with multiple connecting holes. In the above technical scheme, there are three connecting holes on one end of the side panel, and the connecting hole is in the shape of a keyway. In the above technical scheme, the width of the bottom plate is 200-1000mm, the height of the side plate is 60-200mm, and the length of the side plate is 2000mm.

After adopting the above technical scheme, the invention has the following positive effects:

(1) the bottom plate and side plate of the invention are formed in one body, simplifying the production process, improving the production efficiency and saving the production cost; In addition, there are multiple cooling holes on the bottom plate, which can greatly improve the heat dissipation efficiency, effectively improve the service life of the cable, and on the other hand reduce the weight of the cable bridge.

(2) the invention flanging on side panel can be used for bridge frame block instrumentation connection, parallel connection hole on the side panel set up multiple, and shape design for slotting type, according to actual situation to choose the right position of connection holes to connect, make the installation more convenient, can greatly improve the efficiency of the installation;

(3) the present invention is simple in structure, unique in shape, low in cost and high in strength, which is applicable to the installation of power cable and control cable laying.

Specific implementation mode

The invention has a bottom plate 1 and a side plate 2 fixedly connected to both sides of the bottom plate 1; Its features are as follows: the bottom plate 1 and the side plate 2 are formed in one body; A number of cooling holes 11 are also arranged on the bottom plate 1.

Preferably, the heat dissipation holes 11 are round, rectangular, square or keyway shape, and the heat dissipation holes 11 are arranged on the bottom plate 1.

Preferably, the upper part of the side plate 2 is provided with a flanging 21, and the two sides of the side plate 2 are provided with multiple connection holes 22. In this example, there are 3 connection holes 22, and the connection hole 22 is shaped like a keyway.

According to the actual needs of customers, the width of floor 1 can be 200-1000mm, the height of side 2 can be 60-200mm, and the length of side 2 can be 2000mm.

The specific implementation of the above example, the purpose of the invention, technical scheme and beneficial effects for further details, should understand that the above is only for the specific implementation example of the present invention, are not used to limit the invention, all within the spirits and principles of the present invention, did any modifications, equivalent replacement, improvement, etc., shall be included in the protection scope of the present invention.

Contact Us

友情链接: